When shipping against sales orders, StarShip takes the place of the Shipment Data Entry module in Sage 100. StarShip creates a shipment and an invoice in just one step. You would generally ship against sales orders when:

You want to pack items into packages using the standard or ”case pack” method instead of the pick/pack method in Sage 100 ERP. StarShip can automatically pack items based on previously learned packaging scenarios. (For more information about auto packing and packaging scenarios, see Maintain Inventory in the StarShip Help.)

You do not want to store item packing detail in Sage

100 ERP or StarShip. You can just enter the bill of lading body

and StarShip will create an invoice with no packing detail.

When shipping exploded sales kits, you must pack the actual kit item into first-level packaging (i.e boxes), even though the kit item will not be removed from inventory. Otherwise, the kit item will be back-ordered.

You can select an order by scanning the order number or typing the order number directly into the Sage 100 Order field. You can also click the magnifying glass to use the Search/Batch Processing functionality to search for and process one or multiple documents. Note : If you want to ship with the Shipping Assistant, see Using the Shipping Assistant.

Use the available filters to narrow down and sort your search results. Click Add Filter and then enter your specific criteria. Certain filters also allow you to select from a list of existing values.

After selecting the order(s), you can then process the order(s) automatically OR you can load an order and enter or modify shipment detail.

Note : The Order Status column can be used to sort orders by Status. Only the orders with allowed statuses will be allowed for import, based on the setting in Source Interface Setup > Additional Settings.

Process Selected : If you are processing one or multiple orders, StarShip will process the shipment(s) according to the batch settings you select. For more information about batch settings, click here.

OR

To select a single order, double-click the row (or check the box and click the Load Document button) to load the order into the Ship screen. If any line items have previously been shipped, StarShip retrieves related freight information (if applicable). If items have not been shipped before, or line item detail is not mapped to Sage 100, you may need to enter additional information, such as freight class. Next, pack the line items in the shipment into packages.

You can pack the shipment manually, by clicking the Packaging View button. In the Packaging View, drag and drop the items into first level packaging (for example, Box). See example

Line items can be packed using

learned or created packaging scenarios (added or modified in Maintain Inventory). If you've shipped any

of the items before, StarShip retrieves packaging scenarios and automatically

packs those items into first level packaging (boxes, cartons, etc).

By default, auto-packing based on packaging scenarios is not enabled.

You can enable this setting in Setup > Preferences under Shipment

Processing (for Freight or Parcel); check the option, "Automatically

pack items based on packaging scenarios." Control how items are

packed using the related Auto Pack Preference setting below it.

Note: StarShip supports mixed items in one box. However, StarShip can

only learn packaging scenarios for future shipments when you have

one type of item in one package. The auto-learning of packaging scenarios

is optional and can be disabled.

Loose items imported from Sage 100 orders can be packed automatically into a default box. StarShip will pack loose items into default packaging based on the Preferences setting, "When importing orders, pack all loose items into a default package." This is the default setting; if you want to change this default, uncheck this setting in Parcel or Freight Preferences setup under Shipment Processing. Note that this setting is worded differently for Freight Preferences because it takes pallets into account.

If you add items from StarShip inventory, these can be automatically packed into the first, currently selected, or a new default box. They can also be left loose. This is based on the Preferences setting, "When adding items from StarShip inventory, place loose items in ..." The default setting is first package.

Items can be packed using the Shipping Assistant, if it is enabled in Preferences setup, either manually or automatically (based on learned packaging scenarios).

More Information : Line Items

Enter Packaging Details

Packaging

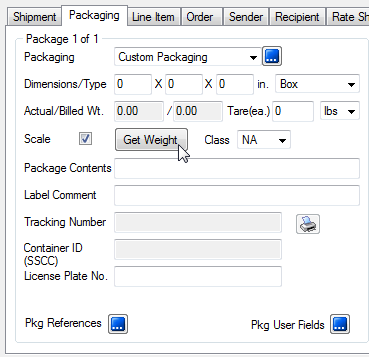

For Parcel shipments, you would enter package detail for existing packages. Remain in the Packaging View and navigate through the packages to weigh them or add package level details on the Packaging tab.

BOL (Freight Shipments)

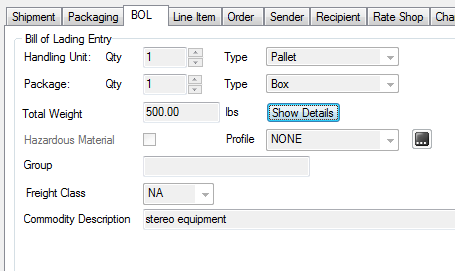

For Freight shipments, StarShip populates the bill of lading using line

item and packing information. Bill of Lading settings in Freight

Setup allow you some flexibility regarding how StarShip converts item

packaging information into the bill of lading body. Typically, similar

items with the same class are grouped under one general description. The

commodity description may be edited on the BOL tab.

You can also manually enter the BOL.

Freight Billing Info

Enter or modify the freight billing information of the shipment, if necessary.

Shipping Method

Select the shipping method - Carrier and Service - on

the Shipment tab, and enter

shipment detail that was not populated. You can also Rate Shop to

select a carrier and service.

Rate the Shipment

Rate the shipment with the currently selected carrier by clicking Rate from the File menu or by pressing Ctrl + Alt + R. To rate shop, click the Rate Shop button in the toolbar or press Ctrl + Alt + S. Select a carrier from the Rate Shop tab. For more information, see Shipping Process > Rating in the StarShip Help.

Ready Date and Time

Enter the shipment's Ready Date (and Pickup Time, for

Freight) on the Shipment tab.

Save the shipment

There are two options for saving shipments.

Save: To save a shipment without processing

it, select Shipment > Save, press Ctrl + S, or click the Save button

on the toolbar. This action saves the shipment as a draft, but does

not process the shipment, request pickup from the carrier, automatically

print shipping documentation, or write back any information to Progression.

The shipment is essentially saved as a draft so you may open it and

make changes.

Ship/Process: To process a shipment, select

Shipment > Ship/Process or select the Ship/Process button from

the toolbar. The shipment is tendered to the carrier. If you set up

the bill of lading and/or labels to print automatically,

they are now generated. StarShip also performs write-back of freight

and notes to Progression.

Shipment Status

Once a shipment is processed, the Shipment Status changes from Open to Processed on the Shipment tab. The status can now be modified.

Invoice Creation/Write-Back

After you Ship/Process a shipment, StarShip creates or updates Sage 100 invoices for each order in the shipment. Here are some notes:

Comments and Miscellaneous Charges from the order are written to the invoice even though they do not appear in the StarShip shipment.

Drop shipped items do not appear in the StarShip shipment, but are automatically backordered.

StarShip writes the freight amount back to the invoice. In the case of a multiple-order shipment, StarShip divides the freight amount equally among the invoices. If StarShip is updating an existing invoice, it will increment the existing freight amount by the amount of the shipment.

If the Ship To address on the shipment differs from the Ship To address on an order, the Ship To address saved in StarShip is the one that will be written to the invoice. The original sales order Ship To address remains unchanged.

StarShip does not support the ”Automatically Print Shipping Documents” setting in Sage 100 Shipping Setup Options.

StarShip allows you to create a shipment against a sales order that already has an open invoice against it only if the first invoice was created by StarShip or Shipping Data Entry. A second invoice cannot be created if the first invoice was entered within Invoice Data Entry. You would then receive the error message: "Currently being invoiced" when selecting the sales order.

See also :